Solids Treatment

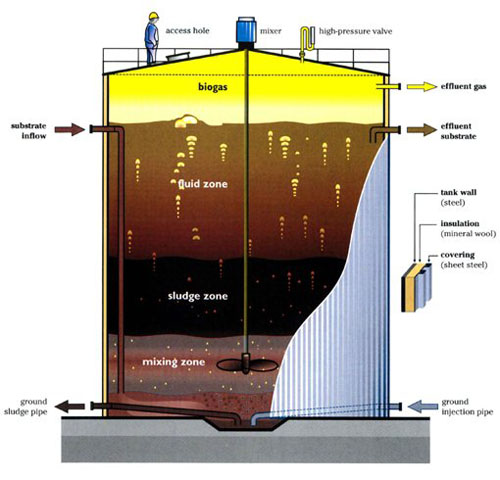

The sludge removed from the bottom of the primary clarifiers gets pumped to one of the District’s four digesters. In the digesters solids decompose and stabilize. The digestion process decomposes and stabilizes volatile solids, which contribute to odors, and eliminates pathogens. Regulations require a minimum of 38 percent reduction in volatile solids; The District’s average reduction is 45 to 60 percent.

After treatment in the digesters, solids are pumped from the digesters at an average of 1.5 to 3.5 percent concentration to holding tanks in the solids dewatering facility. The purpose of the dewatering facility is to increase the solids concentration, or dryness of the solids, to between 18 and 22 percent. At these higher concentrations the solids can be stacked, turned, mixed, and dried.

The District operates belt filter presses to dewater and concentrate the solids content. Belt filter presses use two mesh belts which allow water to pass through the belt while retaining the solids. After an initial gravity separation of liquid and solids, the two belts come together and serpentine through a set of rollers creating pressure on the solids to squeeze additional water out. Concentrated solids discharged from the belt press are referred to as sludge cake. The cake is conveyed from the belt presses into a truck and trailer rig; When filled, the sludge is driven out to a concrete storage pad to be turned, mixed, and dried.