Secondary Treatment

Secondary treatment is not just a second step of primary treatment. It differs significantly in the type of treatment provided. Primary treatment consists of a separation of solids and liquids through physical processes driven by gravity, while secondary treatment consists of biological processing of the organic waste products.

The District’s secondary treatment process is called the “trickling filter/solids contact” process. This process consists of three main treatment components:

- Biotowers and Trickling Filters

- Solids Contact Basins

- Secondary Clarifiers

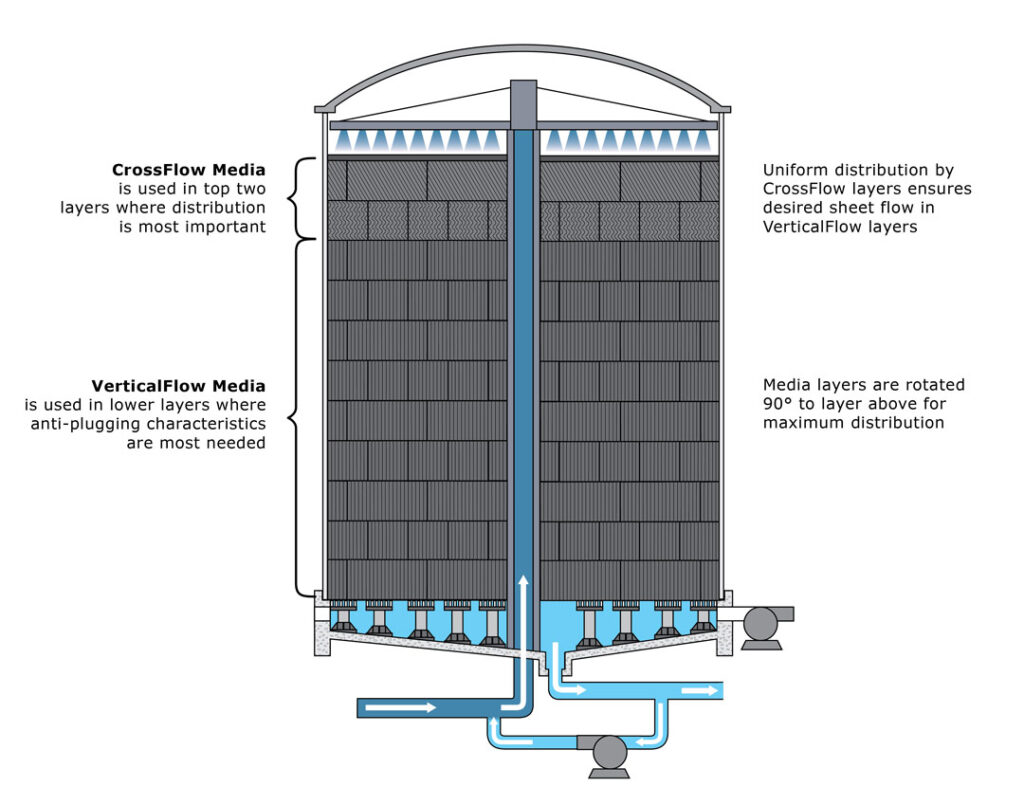

Biotowers and trickling filters are relatively simple treatment units, nothing more than a round tank full of media (rocks or engineered plastic) over which the wastewater is distributed, or “trickled.” The District’s two biotowers are 120 feet in diameter with a plastic media depth of 24 feet. The three trickling filters range in size from 145 feet to 210 feet in diameter with a depth of media from 6 to 8 feet.

A biological mass is grown on the media, whether plastic or rock, and will contain and support a population of microorganisms to perform the actual treatment in the biotowers and trickling filters. The design of the media gives it characteristics providing ventilation, durability, and surface area. The new plastic media used in the biotowers provides much greater surface area per unit than rock has in the past. It is much lighter and provides better ventilation and water distribution.

The biological mass is called zoogleal film or biomass. The biomass forms as a jelly-like mass or slime layer over the surface of the media. The mass consists of microorganisms or “bugs”, primarily bacteria, that feed on the organic waste products contained in the wastewater. As the liquid passes over the surface of the biomass, the bacteria feed on and digest these wastes, breaking them down into more treatable and less polluting forms of matter. If the media is live the houses where bacteria live and the water being treated is the food that they eat, then the mechanism that distributes the flow over the media would be the food delivery service.

The distributor is what most people consider the defining characteristic of trickling filters. The distributor rotates above the media and sprays the water over the surface. The District’s distributors have four arms that spray water through nozzles on both the leading and trailing sides. The movement of the arms is controlled by the strength of the nozzles on the trailing side. The nozzles on the leading side of the arms act as a braking system to control the speed of the distributor. The jets are designed to allow varying levels of flow along the length of the arms so that water equally distributes over the entire surface of the media.

After passing through the biotowers and trickling filters, the flow drains through the bottom of the media. While some of the flow is recirculated back through the biotowers to maintain a constant wetting rate, the remaining flow moves to the next step in secondary treatment.

The solids contact basins are a set of rectangular concrete tanks to prepare the solids particles discharged from the biotowers to settle readily in the secondary clarifiers. Microorganisms produce a polymer, called exocellular polymer, in controlled conditons. The polymer causes solids particles to gather into larger clumps which settle quickly in the secondary clarifiers. Microorganisms are oxygenated and stimulated by precise concentrations of dissolved oxygen in the liquid/solids mixture (called mixed liquor). By controlling the solids concentration of the mixed liquor, and the total time that the solids particles are retained within the solids contact basins determines how effectively the solids clump.

The dissolved oxygen level required is about 2 parts per million and is provided and controlled by an aeration system comprised of blowers and diffusers. Blowers supply air through fine bubble membrane diffusers mounted on the floor of each solids contact basin, similar to the aeration in home fish aquariums. As the air is diffused into the bottom of the basins the mixed liquor is gently mixed to keep the solids from settling and oxygen is added to the wastewater.

There are two basic mechanisms to maintain the desired concentration of solids in the mixed liquor:

- The solids that settle and are removed from the secondary clarifiers are returned by pumping to the head of the solids contact process

- A determined amount of solids are removed (wasted) from the process every day. The wasted solids are pumped to the dewatering facility where they are thickened by gravity belt thickeners to approximately 4 to 5 percent solids concentration before being pumped to the primary digesters.

The mixed liquor then flows into the secondary clarifiers through a vertical inlet pipe centered over the clarifier. Secondary clarifiers, similarly to primary clarifiers, separate the solids through gravity. A flocculation well (circular metal ring) is located at the center of the clarifier extending several feet below the surface of the liquid in the tank. The well serves two main purposes:

- Directs flow downward to minimize potential of solids particles passing directly from the inlet across the top of the tank over the weir and out of the clarifier.

- Slowing flow to create a stilling basin that promotes flocculation (clumping) and settling of solids

The rotating mechanism of the secondary clarifier differs from the primary clarifier sludge rake system in that it removes sludge by hydraulic suction. Constructed of hollow tubes with inlet orifices on the leading side, the arms connect to the return sludge pumps through a center ring and seal assembly at the bottom of the clarifier. As the pumps draw suction, settled sludge is drawn into the arms and separated by pump back to the inlet side of the solids contact basins or wasted to the gravity belt thickeners.

The primary purpose of the hydraulic suction mechanism is to accommodate rapid sludge removal. Rapid sludge removal is very important in the trickling filter/solids contact process, designed to provide conditions which promote the biological production of polymers to promote flocculation and settling. Formation and preservation of the biopolymer is sensitive to the concentration of dissolved oxygen in the process flow; if dissolved oxygen is too low

biopolymer production decreases and becomes ineffective. The longer settled solids remain in the clarifier, the greater the chance of creating low dissolved oxygen conditions which cause low biopolymer production and poor solids settling.

The wasted sludge from the secondary clarifiers is sent to the digesters; to avoid diluting the digesters with less concentrated sludge they need to be thickened using gravity belt thickeners. Secondary sludge is much less concentrated than raw sludge, about 0.25 to 0.5 percent compared to 3.5 to 5.0 percent for raw sludge. The thickening process is accomplished in the dewatering facilty. Gravity belt thickeners operate in the same manner as the first section of belt filter presses.

Mixing secondary sludge and polymer before being fed into the gravity belt thickeners aids in the dewatering process by causing waste solids to flocculate. Then waste sludge evenly distributed onto a porous moving belt allows water to drain through while solids are retained on top. V-shaped plows are positioned on the surface of the belt as it conveys the solids to shift solids and allow liquids to drain as they move through the process. By adjusting

the speed of the moving belt and specific dose of polymer, adjusts the sludge thickness produced. Once discharged from the gravity belt thickener solids are pumped to the digesters for treatment.